Service Hotline400-666-0112

Service Hotline400-666-0112 Service Hotline400-666-0112

Service Hotline400-666-0112

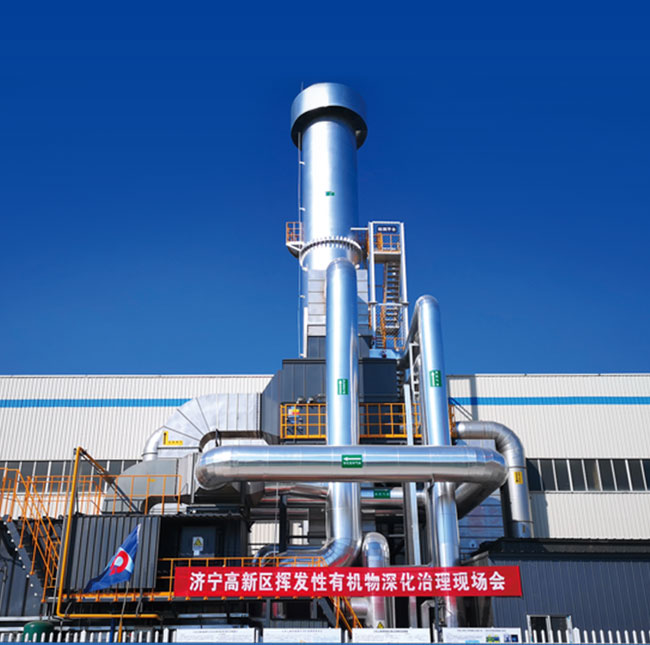

A certain engineering machinery factory located in Jining, Shandong Province produces a large amount of VOCs waste gas during spraying. The main components of the gas include toluene, xylene, methyl isobutyl ketone, styrene, etc. The processing air volume is 464000Nm ³/ H.

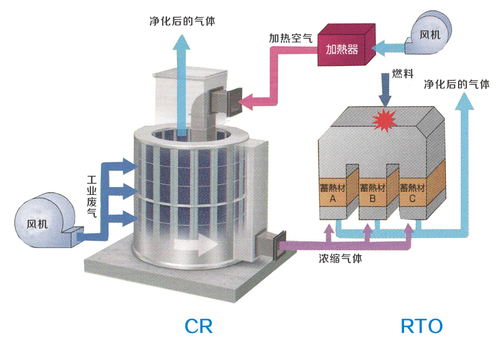

Zeolite wheel+RTO

30times

Design scheme:

The waste gas containing VOCs undergoes pre-treatment to remove large particles and harmful substances to the zeolite wheel, and then enters the zeolite wheel concentration device. After the VOCs components are adsorbed by the zeolite, they are discharged into the atmosphere up to standard. The desorption fan draws a portion of the exhaust gas from the runner to the desorption section, during which it exchanges heat with the hot gas from the heat exchanger. The temperature reaches 150-180 ℃, and VOCs are desorbed from the zeolite runner. They then enter the RTO device, where they are heated to above 800 ℃, oxidized to CO2 and H2O, and discharged into the atmosphere.

Acceptance status:

The project began operation in March 2019, during which the purification effect was very good. After third-party testing, the concentration of VOCs was 5.72mg/m ³, The removal efficiency is above 98.5%, far lower than the emission standard of volatile organic compounds in the surface coating industry in Shandong Province.

Email Address:admin@cadair.com.cn

Email Address:admin@cadair.com.cn Address:14th floor, Greenland Central Plaza Phase II, Xinhua North Road, Tongzhou District, Beijing

Address:14th floor, Greenland Central Plaza Phase II, Xinhua North Road, Tongzhou District, Beijing Shanghai

Shanghai Tianjin

Tianjin Wuxi

Wuxi Guangzhou

Guangzhou