Service Hotline400-666-0112

Service Hotline400-666-0112 Service Hotline400-666-0112

Service Hotline400-666-0112

Dust control strategy

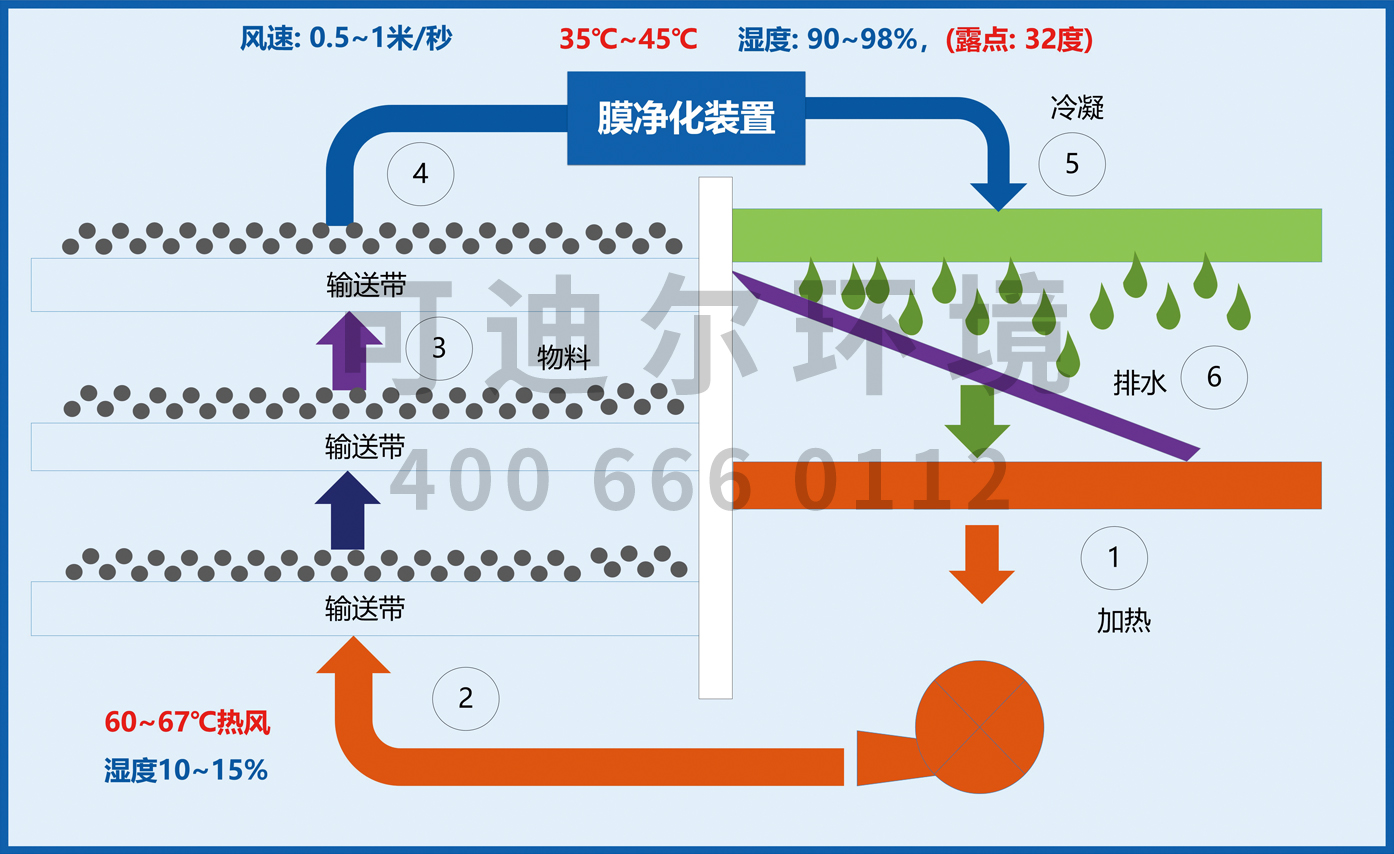

Independently developed membrane purification technology, the airflow is purified more than 200 times per hour, completely removing dust, and ensuring zero dust in the heat source room airflow.

Eliminate clogging of ordinary drying machine filter bags, increase wind resistance, ensure condensation efficiency, and reduce attenuation;

Membrane purification technology firmly locks in extremely fine dust, avoiding the heat exchanger from reducing heat exchange efficiency due to dust adhesion.

No consumables, eliminating the cost of frequent cleaning and replacement of filter bags. Thoroughly solve the problem of high-temperature burning and low-temperature condensation and sticking of dust removal filter bags.

Technical Principles

The second generation ultra-low temperature micro air drying technology utilizes the principle of low-temperature heat pump/waste heat recovery dehumidification, using ultra-low temperature independent air ducts and micro air gradient dehumidification drying method to dehydrate and reduce the amount of wet sludge on the mesh belt. The entire system is fully enclosed in design, with dry hot air without heat loss, effectively preventing odor leakage.

Email Address:admin@cadair.com.cn

Email Address:admin@cadair.com.cn Address:14th floor, Greenland Central Plaza Phase II, Xinhua North Road, Tongzhou District, Beijing

Address:14th floor, Greenland Central Plaza Phase II, Xinhua North Road, Tongzhou District, Beijing Shanghai

Shanghai Tianjin

Tianjin Wuxi

Wuxi Guangzhou

Guangzhou